|

Monday, August 6, 2012

Progress Notes

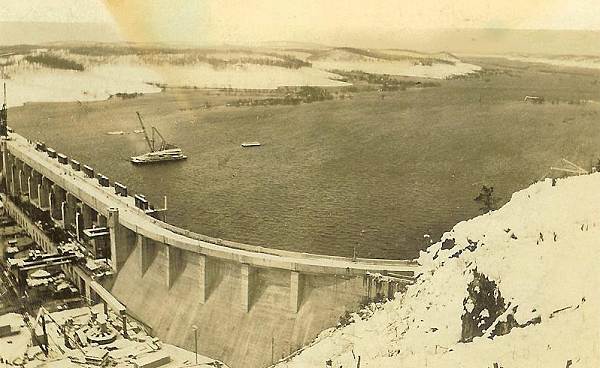

During harsh economic times which we have been enduring in our country the last few years, I feel very thankful that our county has the advantage of being a tourist destination. Our forested hills and valleys, clear streams and abundant natural wildlife are especially appealing to tourists who come from areas where the terrain is plain (and plane) and may have fewer options for outdoor activities as compared to here. Of course, our major attraction is the Lake of the Ozarks completed in 1931. The lake is a reservoir 129 miles long which covers 57,000 acres or 92 square miles, has nearly 1,375 miles of shoreline (more shoreline than the sea coast of the State of California), and impounds 617 billion gallons of water.

The lake was created by the construction of Bagnell Dam in 1931. The dam is located in the western edge of our county.

In several previous Progress Notes I have written about Bagnell Dam and the Lake which you can review at these URL locations (photo 01):

01 Progress Notes websites for Bagnell Dam History

Click image to view document in PDF format with live links

This week, I am going to present an article giving a history of the Bagnell Dam and the Lake which was published in 1981 by what was then Union Electric (now Ameren Corporation). Some of the information is well known but I found quite a number of areas in the article which were new and interesting to me.

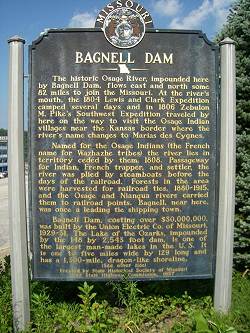

First, here are two signs placed at the west end of Bagnell Dam by the Missouri State Historical Society which offer a brief synopsis of the history of Bagnell Dam and the surrounding area (photos 02 and 03).

02 Bagnell Dam History Sign - Front

|

03 Bagnell Dam History Sign - Back

|

Click images above for larger view |

Now here is the article published by Union Electric in 1981 (Note: Most of the photos are scanned from the old newspaper article and are not of high quality) (photo 04)):

04 Bagnell News - Published by Union Electric - 1981

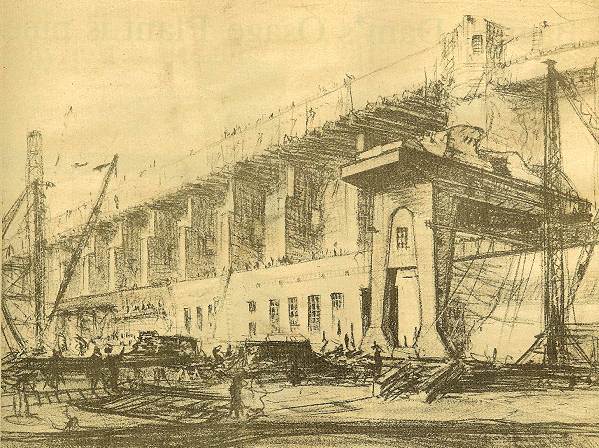

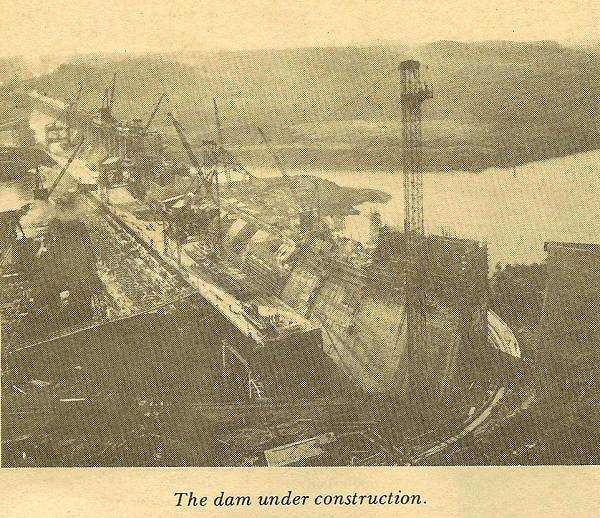

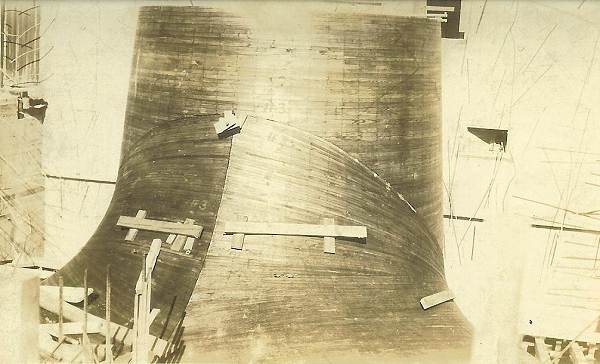

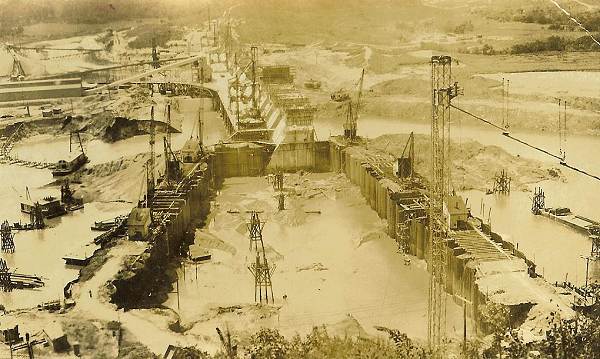

When Bagnell Dam Was Built (photo 05)

05 Bagnell Dam Early Construction

When Bagnell Dam was built, enough lumber was used to construct a sidewalk four feet wide and two inches thick from London to Paris… 13 ½ million board feet.

When Bagnell Dam was built, enough fuel oil and coal were consumed to heat 1800 average St. Louis homes for one year… 4,000,000 gallons of fuel oil and 18,000 tons of coal.

When Bagnell Dam was built, enough concrete was poured to build a standard Missouri Highway 18 feet wide, with a six inch slab, from St. Louis through Kansas City to Topeka, Kansas… 553,000 cubic yards.

When Bagnell Dam was built, enough water was impouned to supply the City of St. Louis with water for 12 years… 87 billion cubic feet.

When Bagnell Dam was built, the dam could have hidden a building 12 stories high and seven blocks long… 148 feet high by 2,543 feet long.

When Bagnell Dam was built, enough car loads of materials were hauled to the project site to reach end to end from St. Louis to Chicago and back… 60,000 cars.

When Bagnell Dam was built, enough lake surface was created to more than encompass the land are of the city of St. Louis…the impoundment surface is 93 square miles and the city of St. Louis encompasses 61.3 square miles.

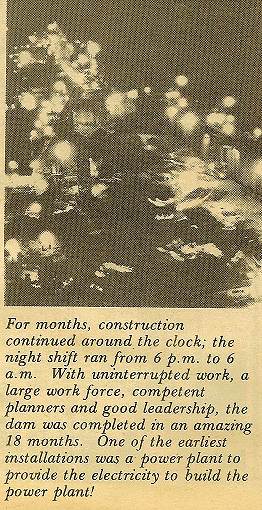

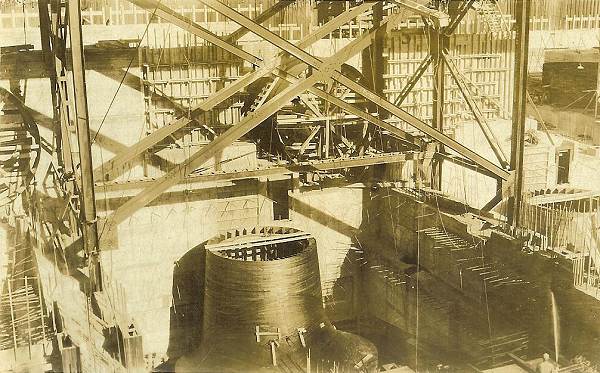

Bagnell Dam Erected in 18 Months Celebrates 50 Years of Service (photo 06)

06 Night Construction

When Union Electric received authorization to build Bagnell Dam and Lake of the Ozarks on July 27, 1929, word quickly spread that the company intended to start work immediately.

It did. Just 10 days later, on August 6, 1929, work began.

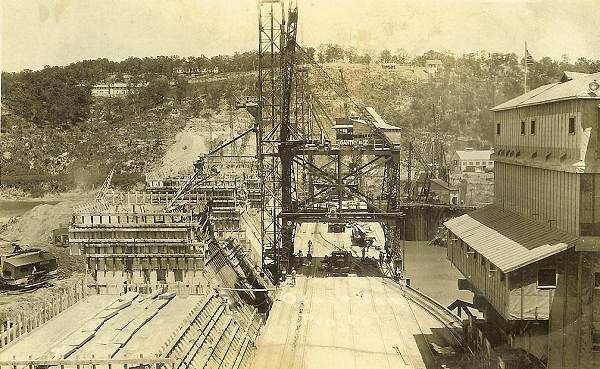

Meeting schedules that called for completion of the largest gravity type dam in the United States within less than two years must have seemed unlikely to many observers.

But, in fact, in the space of less than 18 months, the dam was completed and the reservoir began to fill.

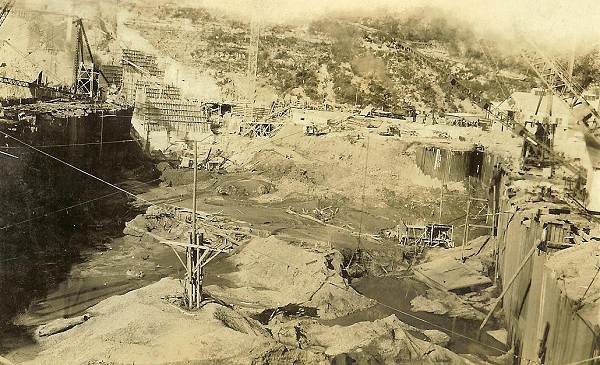

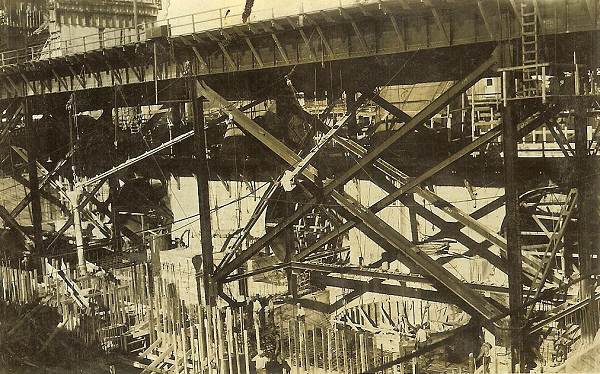

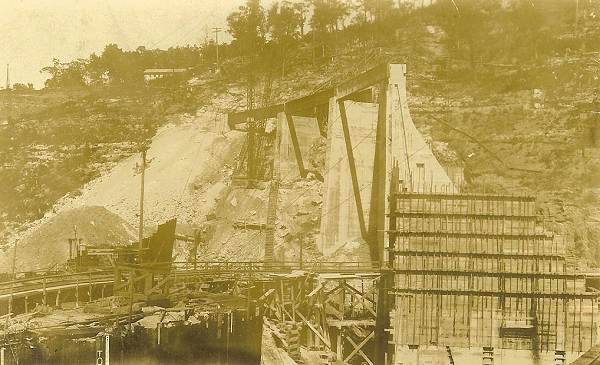

That first fall most of the work entailed grading and excavating. Over the whole project, almost 1,000,000 cubic yards of earth and rock were moved. By spring, concrete pouring could begin. The first concrete was poured April 21, 1930. By November 20, 1930, a Miller County newspaper reported 88 percent of the estimated total concrete had been poured.

“The concrete for the downstream wall of the power station has been poured and headworks concrete is continuing to make rapid progress,” reported the Autogram-Sentinel.

“All of the concrete for the highway on the west abutment and all but two bays of the slab across the spillway have now been poured.”

In all, 553,000 cubic yards of concrete were poured.

Meanwhile, such milestones as opening the diversion channel (July22, 1930) and draining the water from the power station cofferdam (August 5, 1930) had taken place.

During the winter of 1930-31, the 2,543 foot long dam was completed. It had a 511 foot long power station, 520 foot long spillway section and two non over flow retaining sections.

The lake began to fill February 2, 1931, and three months later, on May 20 at 10:45 a.m., the lake reached the spillway crest elevation of 638 feet.

The lake was opened to traffic on May 30, 1931. Water extended up the Niangua, Grand Glaize, Grand and Pomme de Terre river valleys. The reservoir went 129 miles upstream from the dam and encompassed 92 square miles, approximately 58,500 acres. Six Missouri counties can claim portions of the shore line on the Lake of the Ozarks.

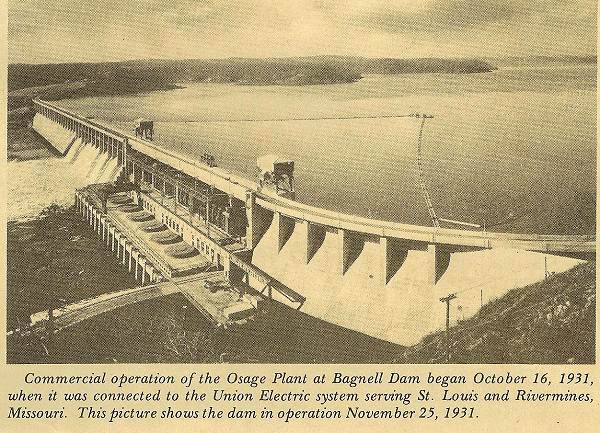

First commercial operation of the Osage Plant began October 16, 1931, when it was connected to the Union Electric system serving St. Louis and Rivermines, Missouri…exactly 26 months and 10 days after dam construction began.

Completion of such a massive construction feat in so short a time was aided certainly by the high production level of the workers on the job and a large labor force, available because of the depression.

Also, there was George P. Jessup, the superintendent of construction for Stone & Webster. “He was a graduate of Cornell, a mechanical engineer, and maybe one of the most talented superintendents that Stone & Webster ever had,” says Walter Malloy, a resident accountant with S&W on the Bagnell project. “He was a noted authority on hydro plants both before and after this project. A great organizer, he established a feeling all down the line with laborers, electricians, carpenters and everyone. They all had great respect for him, and he had respect for them.”

As outstanding leaders are wont to be, Jessup was something of a character. He was known for wearing a white hat. He regularly viewed the work sites by telescope from his front porch. He would quickly descent to the site to admonish a laggard worker whom he had spotted from his perch.

Many credit the successful and rapid completion of the Osage Project to George P. Jessup.

The rapid completion of the project was not indicative of its earliest beginnings. The idea of damming the Osage River near the town of Bagnell had surfaced in 1911. The Missouri Hydro Electric Power Company of Kansas City had done a great deal of preparatory work in anticipation of building a dam when the project got into financial troubles in 1925 and the company had to forego the project.

A man named Ralph W. Street, who had been involved in early studies about building a dam, assumed the responsibility of securing financing. After a discouraging time of near successes and many turndowns, he interested the engineering firm of Stone & Webster of Boston in the project. Stone & Webster redesigned the project so it would efficiently serve the power needs of Union Electric Light and Power Company of St. Louis.

The Project was born.

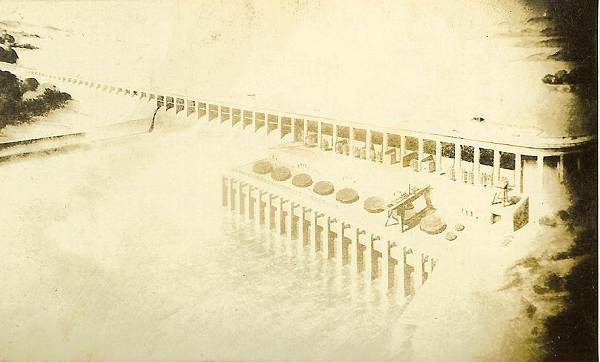

Before Reservoir Filled, Land Was Cleared (photos 07 and 08)

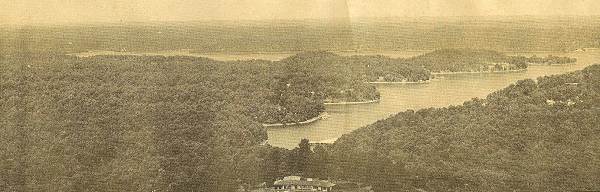

07 Early old photo of Lake

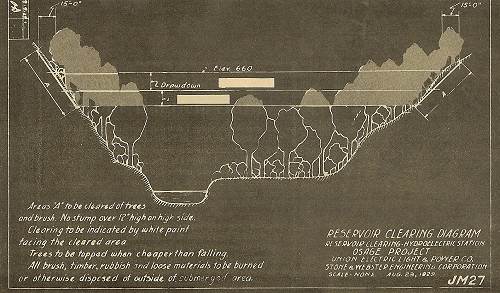

08 Reservoir Clearing Diagram

Click image for larger view

“The rounded hills have been given bowl haircuts up to the eventual water line. The timber has been shorn thence downward. And in the valley the buildings have been razed.”

So wrote a newspaperman in 1931 as he described the lands which would be flooded by the damming of the Osage River.

The Great Osage Project provided an efficient and much needed energy source. Work was provided for thousands during the early years of the Great Depression.

The task of determining just where and how high the water, once impounded, would rise was staggering. All of the almost 60,000 acres of eventual lake area had to be acquired and marked. About 30,000 acres of the reservoir required clearing. The federal license specified that all trees and brush be cut and removed from a line 15 feet horizontally above the 660 foot contour down to 630 foot. Teams of surveyors marked the more that 1,300 miles of shoreline.

After the land was acquired, it was cleared between the highest and lowest marks, giving it the “bowl haircut” appearance noted by the 1931 writer. This acquisition and clearing phase of the project resulted in inevitable relocation of some area residents. The towns of Camdenton and new Linn Creek were established by former residents of “lowland” areas. In addition, from 32 cemeteries and 74 isolated spots, 2,850 bodies were removed and reinterred on higher ground. New roads and railroad tracks were also built to replace those located in the “pool” areas.

Now “the rounded hills” provide the points and inlets along the lake shore to which touring millions throng each year to join the thousands who call Lake of the Ozarks home.

Construction Spared Area From Great Depression (photo 09)

09 Progress Stages of Dam Construction

October 29, 1929, less that three months after Bagnell Dam construction began, the stock market crashed, and the United States entered into a great depression.

But in central Missouri, the economy prospered because the dam was providing work for thousands of people. It was the only major construction project in the United States.

Union Electric had a mess hall that served over 800,000 meals during the construction period. Imagining the economic activity stimulated by this mess hall gives visions of economic prosperity for butchers, grocers, bakers, cooks, waitresses etc.

People rented rooms in their homes and took in boarders.

Every possible location that could be called a store front was pressed into service. Not only were the surrounding towns crowded, but new towns sprang up. Where before only a hillock or valley existed, now a settlement called “Dam Site” or “Spring Camp” or “Connor’s Camp” stood.

Pay rates were as low as 35 cents an hour, but five dollars worth of groceries “filled your car.”

As times were dire in other areas of the nation, people came to Bagnell hoping to get work, even when no hiring was taking place, as this quote from the Eldon Advertiser of June 19, 1930, reveals:

“C.A. Beeson, Chief of Police at Bagnell, rounded up 72 bums in his town one day last week and shipped them over the Missouri Pacific. He said it became necessary to get the men out of town as there was no room for them and nearby farmers were complaining of losing the potatoes and garden.”

But the depression, which caused misery for these 72 “bums” and thousands of other people, did not harm the economy of central Missouri, because Union Electric was building Bagnell Dam on the Osage River.

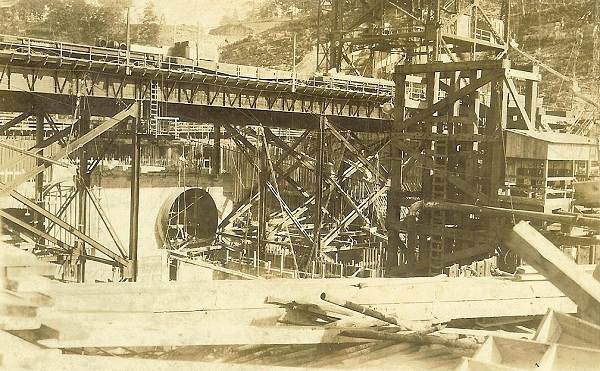

Massive Construction of Bagnell Dam Completed In 18 Months

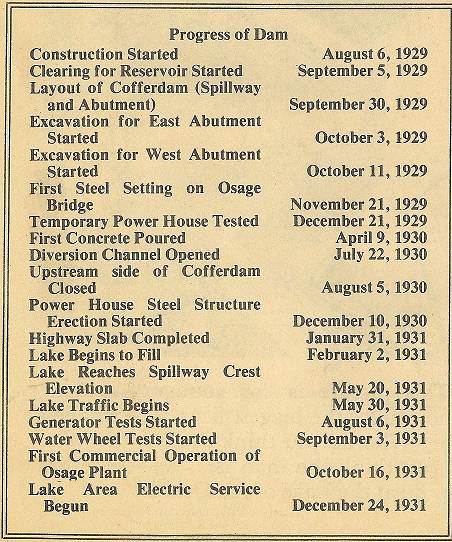

Bagnell Dam, a $30 million dollar undertaking, was built in the remarkable span of only 18 months. Every section of the work was completed on schedule or before:

Consider:

The structure of the power station is of mass and reinforced concrete embedded in rock. Initially, there were six main generating units; two additional units were added in 1953. The spillway section is equipped with 12 flood gates, each 34 feet wide by 23 feet high. The gates are used to control the reservoir water level during flood periods. Each weights 27 tons and is capable of discharging 101,000 gallons of water per second. Concrete piers between the gate openings support a 20 foot wide highway and operating platform above the crest of the spillway. Two 70 ton capacity cranes operate the flood gates and the head gates for the power station.

The first section of the dam to be built was the spillway and abutment portion west of the river channel. Lines of steel sheet piling were driven from the river to the west hillside. A cofferdam was constructed. A construction bridge was built down stream from the dam site, accommodating trains bringing construction materials in. that bridge also supported three gantries which were used in placement of concrete. The concrete plant was on the west side, downstream from the construction bridge. Sand and gravel to make concrete were dredged from the Osage River bed 3 ½ miles downstream.

The dam is 2,543 feet long, has a 511 foot long power station, 520 foot long spillway section and two non overflow retaining sections adjacent to the river banks.

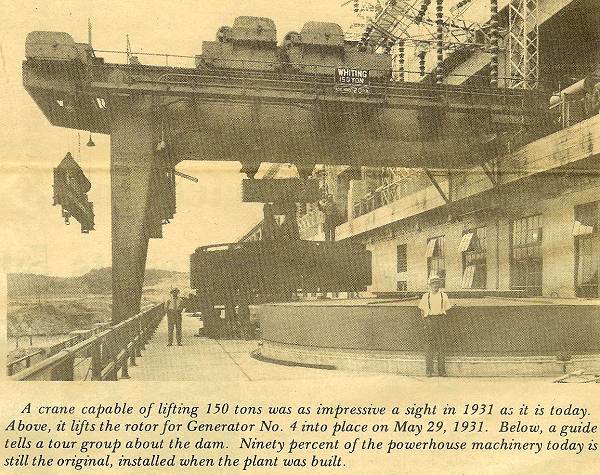

Ninety percent of the powerhouse machinery today is still the original, installed when the plant was built…a testimony to the skills and craftsmanship of the people who built it 50 years ago.

Why a Dam? Builders Have Many Good Reasons (photos 10, 11 and 12)

10 Some facts about Bagnell Dam

11 Crane Lifting Generator

12 Spectators Under Crane

Why does anyone build a dam?

There are at least five good purposes for which a dam can be built:

1. To generate electricity

2. To control floods

3. To improve navigation

4. To store water for periods of low rainfall

5. To create a lake for recreation or other purposes

Many dams do several of these. The Osage project was undertaken primarily to generate electricity. Water recreation was a second, but nonetheless large benefit.

Union Electric’s dam at Keokuk Iowa, built in 1913 on the Mississippi River, served to deepen the river upstream as well as to generate electricity.

Tennessee Valley Authority dams were intended to control flood problems, but they also generate electricity.

Damming a stream has many considerations. The value of the land to be flooded, the market for any electricity produced, the potential usage of the reservoir for recreation and navigation, the annual rainfall….all must be carefully measured against the costs of building and maintaing a dam.

Dams can be much higher or lower than Bagnell, and much longer or shorter. Bagnell is 148 feet high and 2,543 feet long.

Recreation a Second Benefit, Available To Many (photos 13 - 19)

13 Picnic Area on bluff over look of Lake

14 Modern homes built in recent years

15 Water Skiing once predominated as Lake Sport

16 Many Golf Courses

17 Trail Riding in the Ozark Hills

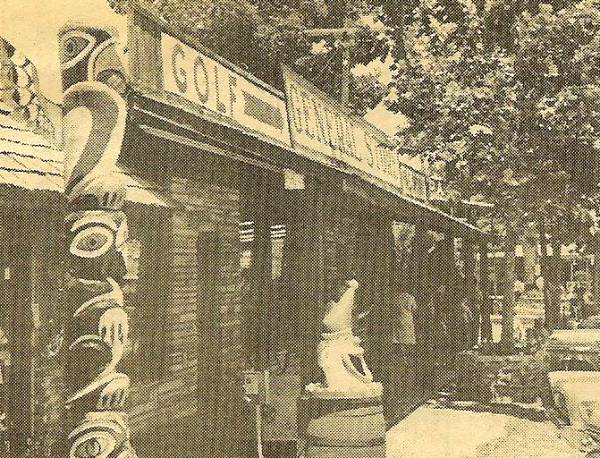

18 Multiple Souvenir Stores - Some Locally Made

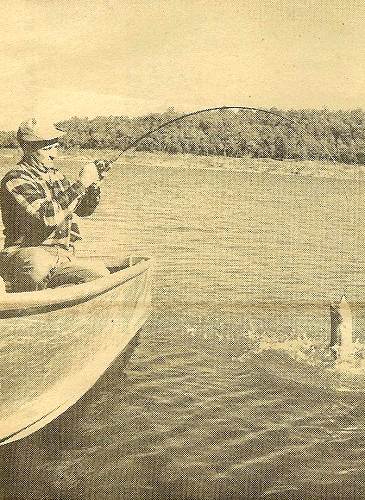

19 Fishing remains most Popular Sport

Engineers predicted accurately the amount of electricity that Osage Plant could produce. But no one could possibly have dreamed of the millions of hours of recreation that the Lake of the Ozarks would provide for tourists and local residents in the fifty years that followed.

Early fishing camps were joined by “tourist courts” with serviceable outside facilities. The pleasant early resorts hosted small groups. A few tourists returned to the lake area as residents. People built summer or weekend homes at the Lake.

Now homes built are likely to be year round residences, often quite large and in styles to rival fancy suburban neighborhoods. More and more people who enjoyed the lake as honeymooners or vacationers eventually retire to a lake area home.

The increased usage of air conditioning and the building of interstate highways have made lake recreation even more desirable, accessible and convenient.

Increases in tourism have meant more investment in the lake area. Over 35 million dollars have been invested in luxury resorts in the last decade, and improvements and construction of new and existing lake homes and resorts is running about $35 million annually according to the Lake of the Ozarks Board of Realtors.

Recent developments provide more luxurious facilities like swimming pools, tennis courts, fine restaurants, convenient marinas, golf courses, bowling alleys and ice skating rinks.

Today, the Lake of the Ozarks area boasts of more that 200 lakeside resorts, hotels and motels which can accommodate over 25,000 persons. Annual visitor estimates range between 5 and 10 million people. Interestingly, a vacation day can cost as little as $15 per person or, for those who have it, as much as $350.

One source lists more than 1,500 boats over 38 feet long permanently moored on the lake. The Missouri State Water Patrol estimates weekend pleasure boats during the tourist season of May through September number in the neighborhood of 35,000 craft.

Tourist related businesses such as movie theatres and museums offer people of all ages things to see and do. Shows, festivals, contests and professional entertainers bring a cosmopolitan air to the people who flock to the Lake of the Ozarks…created 50 years ago by the building of Bagnell Dam.

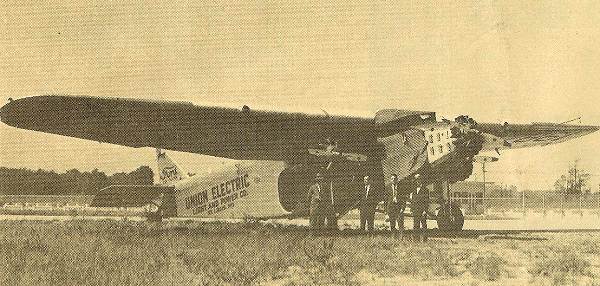

Aerial Photography Just a Fledgling In 1931 (photos 20, 21 and 22)

20 Union Electric Airplane

21 Caption for Union Electric Airplane

22 Union Electric Airfield

As the dam neared completion, Union Electric asked Stone and Webster to make an aerial photograph of the reservoir area including lands to be flooded and all land within one mile of the future lake shore.

John Barjenbruch, now retired and living at Camdenton, worked for Stone and Webster as a young engineer fresh out of the University of Illinois. He was asked to be the cameraman.

“Aerial photography was very new then, and we didn’t have a book on how to do it,” says Mr. Barjenbruch. The methods they employed, although seemingly primitive, had remarkable results.

Using the Union Electric Ford Tri Motor plane, the photography crew mounted the camera on two spirit levels through a hole cut in the cabin floor. Barjenbruch’s job was to watch the spirit levels on the device holding the model K-T Folmer Aero camera to make sure the camera was level when the photos were shot.

While Barjenbruch shot the pictures, another employee timed the shots with a stopwatch. Because the plane made so much noise his voice could not be heard, he blew a whistle to signal Barjenbruch to take the next picture and hand crank the film through the camera to the next frame.

The camera filled the hole in the floor, and Barjenbruch says he never saw what he took a picture of…keeping the camera level was his most important task.

They made some 7800 exposures on Eastman Pan Chromatic Aero Film No. 75, which gave a negative 7x9 inches. The edges of the pictures were distorted, and so, purposely, they took overlapping views so that the centers of the pictures, when matched up, gave few distortions.

The plane flew at 5,900 feet and was piloted by Union Electric employee Phil Love. “He was a good pilot, one of the best, and very safe,” says Barjenbruch. The plane ride, however, made most people airsick, and Barjenbruch says that his chief qualification for cameraman was that he didn’t get sick.

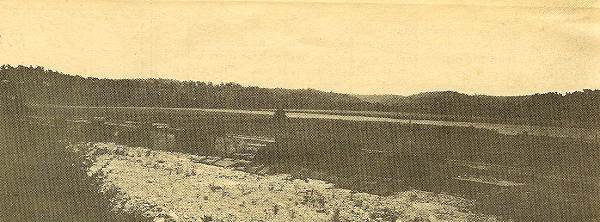

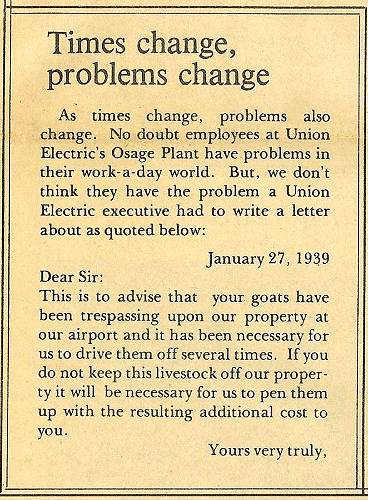

The landing field was just a graded bottom land pasture with a small asphalt patch at one end. Landing on it, according to another Stone and Webster employee, “was wicked” because of the wind and rough field. Sometimes unusual problems arose as recounted in this letter to Union Electric (photo 23):

23 Goat Trespassers

In addition to the pilot and the man with the whistle there was a relief pilot and a flight engineer who coordinated the plane’s path, altitude, speed and wind with the photographer’s readiness to shoot.

They photographed approximately 700 square miles in this manner, producing pictures which were on the scale of one inch equaling 500 feet. Later, on the ground, the prints were matched together. During preliminary field work the wooded hill land had been marked with lime at intervals with symbols of a square, Maltese cross, circle and triangle, 30 feet in outside diameter. Barjenbruch worked on that crew, too. These marks permitted almost perfect matching to give some 64 four foot square composite pictures showing the topography of the entire area.

Barjenbruch later worked for Union Electric Land and Development Company, moving from the Lake area in 1938. Many times in his career he used aerial photography, particularly in transmission line surveys, but the Osage Project was his first and last job as a cameraman.

Teletype Proved Itself (photo 24)

24 Teletype Operator

Teletype carried the messages necessary between the dam’s construction site, Union Electric’s office in St. Louis and the Stone and Webster Engineering Company home office in Boston.

“This job was the first time Stone and Webster used teletype,” says Walter Malloy, who was a resident accountant with Stone and Webster. “It was so successful,” says Johnston McLeod, an onsite purchasing agent, “that they put it on all S&W job sites after that.”

Besides quickly transmitting such helpful things as engineers’ corrections and requisitions, the teletype gave a printed record of communications between the offices and the job site.

Almost 17 miles of teletype paper was used in the Bagnell project. The main reason that teletype was tried in preference to the telephone was that there was only one telephone line going to the Bagnell area, and if it were in use by local residents, the company had no way to communicate with the construction site.

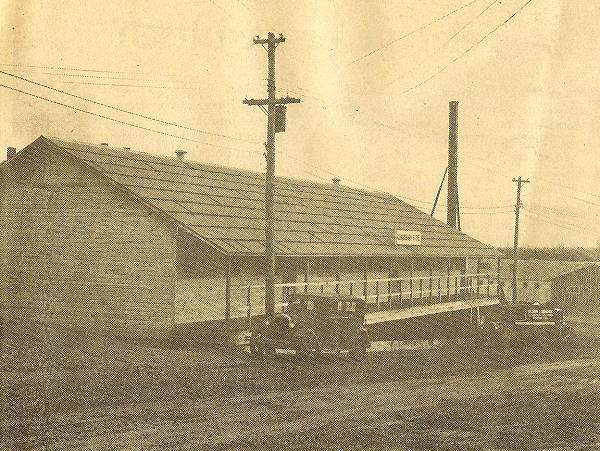

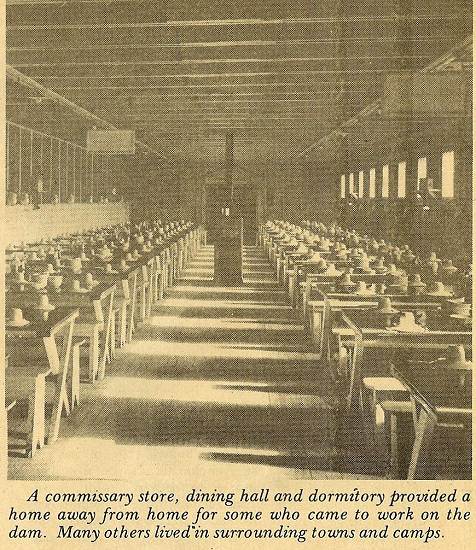

Workers Had a Home Away From Home Near The Dam’s Construction Site

(No Narrative, photos 25 - 32)

25 Camp Store

26 Inside the Store

27 Dormitory

28 Primitive Mechanization

29 Earliest Homes for UE Employees

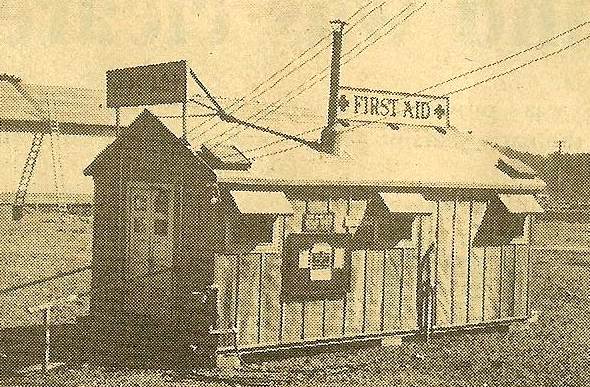

30 First Aid Building

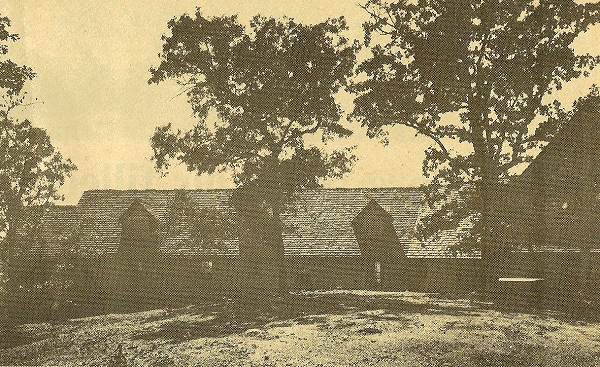

31 UE Lodge

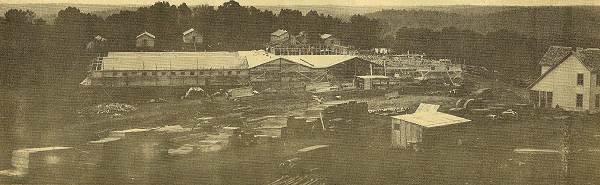

32 Overview of Workers' Residences

Who Was First To Cross The Dam? It’s Controversial… (photos 33 and 34)

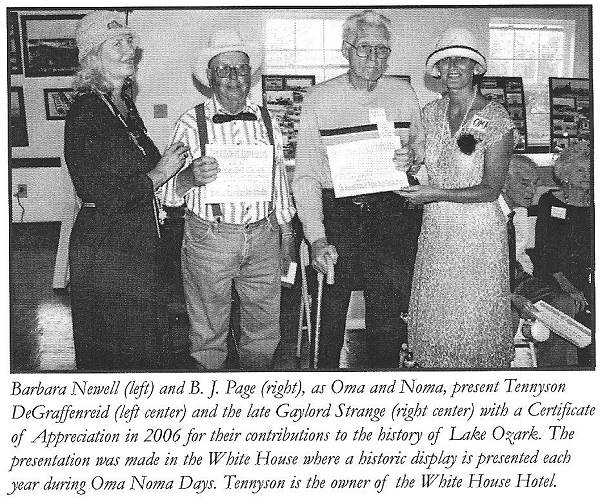

33 Oma and Noma DeGraffenreid

34 Tennyson DeGraffenreid at White House - Weaver Collection

Who was the first person to cross the highway atop Bagnell Dam?

Controversy still exists about who was actually the first. We have this charming account prepared as part of the DeGraffenreid family history contained in a book about the Bagnell Dam area:

“Memorial Day, Saturday, May 30, 1931, Mrs. L.C. DeGraffenreid of 618 South Seventh Street, Kansas City, Kansas, and Misses Noma and Oma DeGraffenreid of near Bagnell, driving a 1928 Chevrolet Coach, claimed the distinction of being the first ones to drive across Osage (Bagnell) Dam Saturday morning when the dam was opened to the traveling public.”

“They left G.R. DeGraffenreid’s home at 4 a.m. and arrived at the west end of the dam at 5:00 a.m., but the barriers were not taken down until 6:a.m.

“They sat there in the car while the rain was pouring down and waited patiently as they wished to be the first to cross the dam. So when the 6 a.m. whistle blew they went speeding away over the big dam. While crossing they met four other cars and the Chevrolet sped away as the occupants strove to be the first to drive off the dam. When they arrived at the east end, they looked back across the lake and the others had not yet driven off the dam, so the three ladies went on their way very much elated to know that they were the first to cross the huge dam after its official opening to traffic.

These three women are still living and are aunts of the operating foreman at the Osage Plant, Tennyson A. DeGraffenreid. A foot note to the above piece indicates that it took an hour to go the five miles from the town of Bagnell to the dam because of the condition of the dirt roads.

Although this account sounds quite valid, we must also include that the Eldon Advertiser of June 4, 1931, reported that Mr. J.T. Ritter, superintendent at the Stone and Webster Engineering Corporation hospital at the dam, drove the first car over the dam after it was officially opened.

The account says Mrs. Ritter drove a new Auburn-Eight, and that she was given the right of way over some other cars that were waiting because she had “a good many friends” at the dam.

The paper reports that 1,771 cars crossed the dam on Saturday and 2,914 on Sunday…the first two days the highway was opened. Many others parked on both sides of the river and did not cross over the dam. Perhaps they preferred that others test the dam’s strength.

Bagnell Dam’s Osage Plant Is Pinch Hitter (photo 35)

35 Bagnell Dam soon began operation

Osage Plant at Bagnell Dam is Union Electric’s pinch hitter. People are surprised to learn that the amount of power generated at the Osage Plant is less that two percent of Union Electric Company’s needs. But that two percent is highly valued for three reasons:

1. It is inexpensive, practically immune to inflation because the price of water does not accelerate.

2. During the time of maximum demand, at the height of the air conditioning season, is when power at the Osage Plant is most available.

3. Power can be produced from the plant on very short notice. It takes much less time to open a valve to a turbine than it does to get up steam in a boiler at a fossil fuel or nuclear power plant.

As water passes through the dam, the pressure of the falling water spins the water wheels which drive generators that produce electricity.

The average yearly output of Osage Plant is 440 million kilowatt hours. Each of the plant’s eight generators has a capacity of 21,500 kilowatts; however, on occasion, the plant has been able to reach a generaton peak of 220,000 kolowatts…enough power to meet the household needs of 225,000 people.

Osage’s generators spin at a rate of 112 ½ revolutions per minute and develop 13,800 volts each.

The plant’s eight water wheels weigh 50 tons each and the solid steel shafts extending from the water wheels to the generators each weigh 37 ½ tons

When the plant is operating at full capacity, it takes 240,000 gallons of water a second to drive these eight generators.

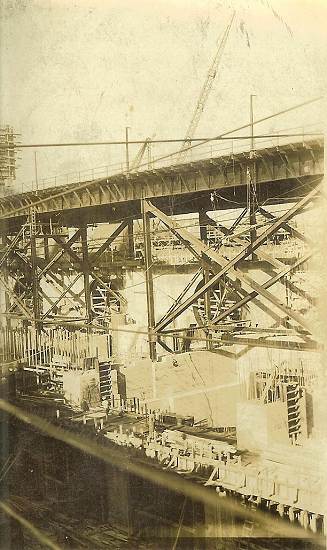

Tours of Bagnell Dam Popular and Convenient (photo 36)

36 Dam Under Construction

The Osage Plant at Bagnell Dam has more visitors each year than any other Union Electric plant. More that 50,000 went through last year.

The appeal of the tour is easy to understand. There is no other similar plant in this part of the country, the tour is free, it takes only a half hour and there are tours at seven convenient times every day. They start at 9:30, 10:30 and 11:30 in the morning and 1, 2, 3 and 4 in the afternoon.

Tours follow a route carefully laid out to permit the visitor to see a lot, yet walk only a short distance. Guides capable of answering just about any question conduct each tour group. Most of the information that visitors get, though, is tape recorded and comes over loud speakers along the tour route. Speakers are turned up so that people can hear above the plant noise.

Signs along the highway at the dam direct visitors to the starting point for tours, the plant reception room. There, seated before a large cutaway drawing of the power plant, visitors are given a short history of the project and an explanation of the part the plant plays in providing electricity for the company’s customers.

After the briefing in the reception room, visitors are led out onto the flat roof of the plant. Stopping at points along the lengthy roof, the visitors are shown various components of the dam and plant. They also get a view of the Osage River below the dam, which remains much as it looked before the dam was built. This stretch of the river is a favorite area for anglers.

The final stops on the tour are inside the plant. There one gets a close look at one of the eight massive shafts, 28 inches in diameter, which connect the turbines, on a level below the tour group, with the generators, over their heads.

Most of the plant equipment is original, installed over 50 years ago. Thanks to thorough lubrication, sound design and careful maintenance, it has a remarkable record of service.

Interesting That Element of Chance

As might be expected in such circumstances, the pool that began to form in the reservoir on February 2, 1931, was not the only pool resulting from the water backing up to make the Lake of the Ozarks by May of 1931.

An old letter from a woman employee in an office concerned with the construction reads:

“On the morning of the 20th Mr. Davidson told me on the telephone that the lake reached the 638 contour officially at 9 a.m. My guess was May 20th at 10 a.m. However, this bunch around here refused to pay off until they get an ‘official’ report….I called Mr. Davidson on the phone this morning and he confirmed his former statement, but they still refuse to listen to reason. Undoubtedly, there is somebody whose word would be considered as ‘official!’ I’m thrilled to death over winning the money, and, of course, this bunch up here are taking advantage of me and having a lot of fun at my expense.”

The assistant works engineer responded giving the official word: “The Lake of the Ozarks reached elevation 638 at the dam and started continuous spilling over the spillway at 10:45 a.m. on May 20. May I extend my congratulations to you as an estimator of hydraulic phenomenon. I hope that on the next project I may establish connections with you to get you to do some guessing for me on other problems which cause the hydraulic engineer much brain fag.”

(She got the money.)

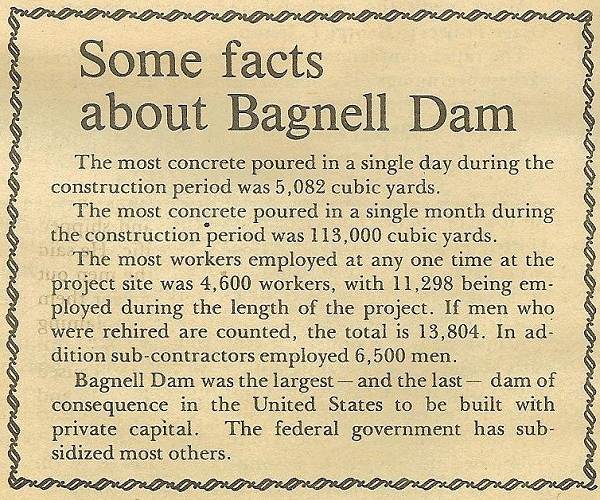

Some Facts About Bagnell Dam

The most concrete poured in a single day during the construction period was 5,082 cubic yards.

The most workers employed at any one time at the project site was 4,600 workers, with 11,298 being employed during the length of the project. If men who were rehired are counted, the total is 13,804. In addition sub contractors employed 6,500 men.

Bagnell Dam was the largest..and last..dam of consequence in the United States to be built with private capital. The federal government has subsidized most others.

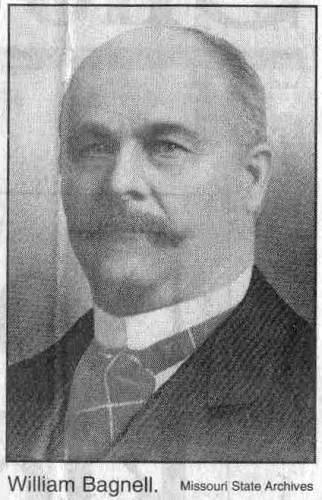

Where Did Bagnell Get Its Name (photo 37)?

37 William Bagnell

Q.Why is the dam built for Union Electric on the Osage River called “Bagnell?”

A. The name was taken from a town near the site.

Q. How did the town get its name?

A. An old newspaper account relates that the town of Bagnell was named for a Bill Bagnell, who started a store on Little Gravois Creek. In the early 1880’s, the Jefferson City, Lebanon and Southwestern Railroad wanted some grading done at its property across the creek from Mr. Bagnell’s place. He agreed to do the grading if the railroad would name the switchbed at the end of the line for him. So, Bagnell Dam’s name came from a man who earned a certain niche in history by doing some property grading.

At this point I will need to interject editorially that the above version of the story about the origin of the name of the town of Bagnell is the first I have read. I have written previously about the origin of the name of Bagnell at a previous Progress Notes. If you want to read what I believe is the true story of the origin of the name Bagnell for the town of Bagnell (and subsequently the Bagnell Dam, I refer you to the Progress Notes of April 7, 2008.

For those who are collectors or just would be interested in seeing more original photos of the construction of Bagnell Dam, I have a series of photos given me by former Tuscumbia native, Tom Albertson (photo 38).

38 Tom Albertson - THS Grad 1950 - Grandson of Emma Johnson

Tom said his father worked as a laborer on the Dam project when he collected the following photos (photos 39 - 52):

39 Bagnell Dam

40 Bagnell Dam

41 Bagnell Dam

42 Bagnell Dam

43 Bagnell Dam

44 Bagnell Dam

45 Bagnell Dam

46 Bagnell Dam

47 Bagnell Dam

48 Bagnell Dam

49 Bagnell Dam

50 Bagnell Dam

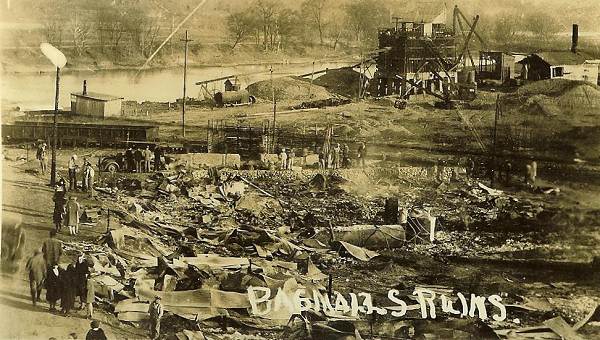

51 Bagnell After Fire

52 Bagnell Dam

Photo 51 above was taken of the residue of one of the fires which plagued Bagnell during the early days after the Dam was built. You can read about the Bagnell fires at these previous Progress Notes:

http://www.millercountymuseum.org/newspapers/bagnellfire.html

http://www.millercountymuseum.org/archives/081020.html

http://www.millercountymuseum.org/archives/110815.html

http://www.millercountymuseum.org/communities/bagnell.html

http://www.millercountymuseum.org/archives/070917.html

A couple of weeks ago I was hosting at the museum and met visitors Mr. and Mrs. Donald Stewart of Castleton, Illinois. Donald had been raised south of Waynesville where his family ran a grocery and general store. When we came to the area of the museum which recounts the history of mills in the county, Donald was very fascinated by the old cash register used by the Anchor Mill Company of Tuscumbia (photo 53).

53 Donald Stewart and Anchor Mill Cash Register

Something I had not paid much attention to but pointed out to me by Donald was the rectangular white porcelain attached to the cash register just below the keys. I had seen it many times but hadn’t wondered much about it. However, Donald said he was very familiar with porcelain being attached to cash registers since the one his father used had one.

He told me that years ago when coinage was not standardized, store owners could distinguish between fake and officially minted coins by how they “rung” when struck against the porcelain. I had never heard about that but sure enough, a quick search on the internet revealed these two articles:

http://www.collectorsweekly.com/stories/32065-1946-national-cash-register

“I didn't know until recently that the white porcelin stone was to "Tap" the coins against to check to see if they were real......"No wooden Nickles" !!!”

http://www.steamboatspringschurch.com/resources/devotions-by-dave/56-love-as-a-proof-of-salvation.html

“I was watching a show on TV the other day about a guy in Las Vegas who restores antiques. A man had brought him an antique cash register for restoration. The old cash register was in rough shape. One thing I noticed as I watched was that just below the keys that rang up a purchase was a piece of marble which I thought was just an ornamentation. But the man doing the restoration explained to his customer that the piece of marble was a functioning part of the cash register. It seems that at the time the register was being used there were many people trying to pass fake coins as real tender. Business owners would tap a coin on the marble to ascertain from the sound it made whether it was a real coin or a slug. The restorer even demonstrated by taking a real coin and tapping it on the marble....the real coin made a ringing sound. Then he took a slug and tapped it on the marble....it made a dull clunk.”

The lesson to me is that you can always learn something new at the Miller County Museum, no matter how much you think you know!

That’s all for this week.

Joe Pryor

Previous article links are in a dropdown menu at the top of all of the pages.

|